Machinery Condition Monitoring Systems

IPC is a young engineering company based on outstanding experiences and knowledge on the process industry machinery and devices. Thanks to long experience developed on process machinery IPC has designed a special line of computerized machinery panels dedicated to the machinery monitoring and diagnostics.

These systems are the result of a long experience on process plants operations, rotating machinery design, manufacturing and commissioning practice, developed serving in major world class industry leading companies.

Importance of machinery in the process plants

Rotating machinery rapresent one of the major players among the process plant assets. Rotating machinery are infact very often used in the process industry for plant-critical services. Machinery failure often result in huge costs in general terms of both loss of production and maintenance and repair time and money.

Assure and guarantee the safe and optimal operative condition for rotating machinery is than often understood as one of the primary maintenance goals for the process plant management teams.

Using advanced technique for machine performance prediction.

IPC Monitoring systems are focused to continuous monitoring and a continuous evaluation of the machine performance based on the comparison to Performance expected .as per OEM. This quantitative performance evaluation approach allows to implement predictive maintenance strategies optimizing schedules of interventions for max production and minimum costs.

IPC monitoring systems have been designed to achieve maximum machinery availability, minimum downtimes and optimization of maintenance activities.

New advanced monitoring system embeds sophisticated algorithms for machinery modeling along with hydraulic or thermodynamic calculations based on most recent theories. IPC monitoring systems are specially suited to monitor pumps and compressor.

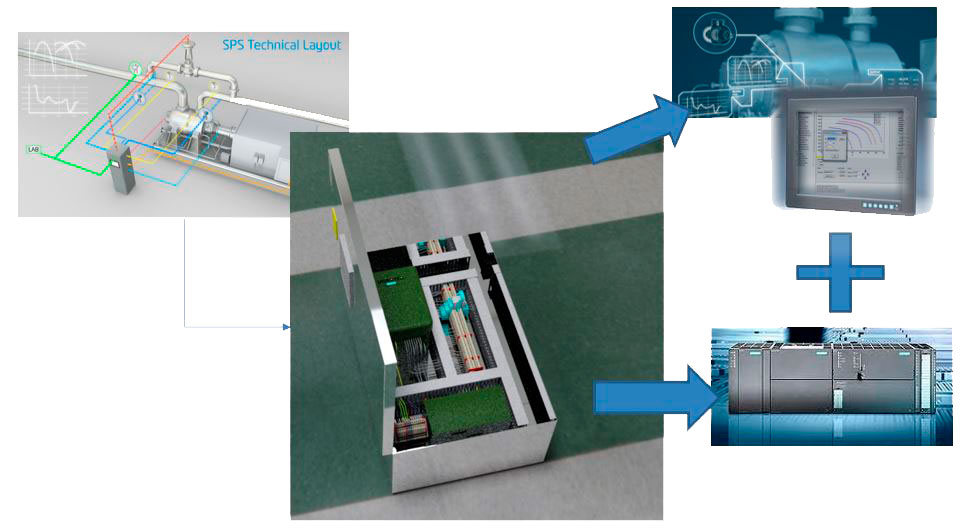

PC/PLC based architecture allows to bring to machinery panel level all the computational power necessary to predict machinery behavior as per OEM expectations and use these information to continuously evaluate the machinery healthy status.

IPC rotating machinery control systems are designed to provide a continuous automated surveillance for process plant. The basic concept implemented into IPC monitoring Systems is to compare machinery performance during real operations (actual performance), to performance developed by the machine in optimal healty status, for example test performance or other type of refernce/design data (in general expected performance).