Control Valves Custom Engineered

The IPC Engineering Team is specialized in the development of new equipment, maintenance and repairs, as well as engineering and production for safety and control valves:

The IPC Engineering Team is specialized in the development of new equipment, maintenance and repairs, as well as engineering and production for safety and control valves:

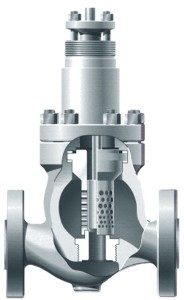

The GVCH type valve is a control valve capable of covering extensive fields of applications. The constructional dature of the multihole cage, locked between body and bonnet, perform the function of sliding the piston plug along its full strike, thus obtaining a better rangeability.

The machine drillings is designed to reduce the negative effects due to the fluid high velocity (erosion, cavitation, noise level).

The special design allows self-centering between plug and cage, thus reducing all clearence deriving from the machining tolerances. The recovery factor value is 0.95;

The rangeability is 50.

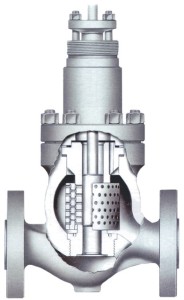

The GVLN type valve is a control valve capable of covering extensive fields of applications.

The GAGE trim allows the fluid velocity in the vena contracta to be controlled when high pressure drops occur, thus reducing resultant negative effects (erosion, cavitation, noise level).

This type of trim makes it possible to obtain a silent valve without silencer employement. The recovery factor value is 0.98.

The rangeability is 100, with special execution up to 200.

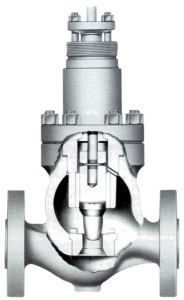

The GVPC valve is a control valve capable of covering extensive fields of applications.

The particolar body shape gives low load losses, high recovery factors and high rangeability. The trim is made up of a contoured plug with linear and equiexponential caracteristics, or ON-OFF and seat. The plug is made from bars or forged and is connected to the drive stem by thread and pin. The plug guide is performer by a bush inserted in the bonnet.

The seat is obtained normally from forged tubeand it is threaded to the body. Besides the seat is welded to the body by seal soldering for rating 900÷2500. The UPC valve can be equipe with bellows for dangerous fluids and with soft seat to comply the leakage requirements of ANSI B16.104, class VI. The recovery factor value is 0.82.

The rangeability is 30÷1.

Bellino is a family-owned and operated company founded 30 years ago initially specialising in mechanical precision of engineering components according to customers’ requirements. Major partnerships were formed with customers most notably Nuovo Pignone. Over the years the company has expanded its operation to include the design and manufacture of Severe Service Control Valves combining a blend of proven expertise, innovation and skilled engineering in this valve specialist market. Today the Company is proud to be one of the leading Italian suppliers, confirmed by special End Users Qualifications from ENI, ENEL, SAIPEM and EDISON.

IPC has the know-how to provide engineering and manufacture of metal seated, high pressure ball valves which can be applied in all kinds of severe environments conditions.

Our products have been widely used in Chemical, Petrochemichal and Power Plants, Oil & Gas,Off-Shore, Refining, WaterTreatment & Energy Generation.

Alas Meccanica is a family-owned and operated Company founded in 1976 initially specialising on the precision machining of engineering components based on customers’ engineering drawings. Major customers and partnerships include Nuovo Pignone and Pentair. In addition Alas Meccanica is also involved in the design and construction of special machining equipment for special components. Alas Meccanica through steady, continuous growth has expanded its scope of supply to include “in-house” design and manufacture of industrial Ball Valves and today is proud to be one of the leading Italian suppliers.

IPC S.r.l. cap. soc. i.v. 10.000 euro - Cod. Fisc. e P.IVA: 08848790724 - R.E.A. BA n.ro: 654401

Industrial Plants Consultants S.r.l. cap. soc. i.v. 110.000 euro - Cod. Fisc. e P.IVA: 06486030726 - R.E.A. BA n.ro:489512