Surge Protection System |

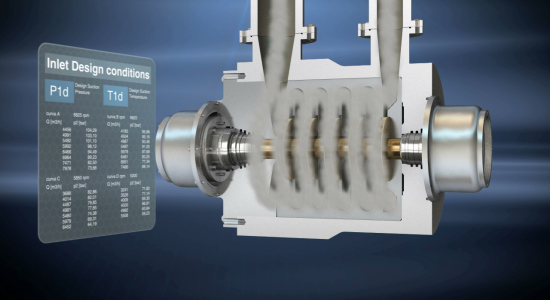

SPS is designed to provide a FULL PROTECTION for centrifugal compressors, it allows to avoid surge in every possible compressor operating condition. SPS embeds a thermo-mechanical engine to predict compressor performances and surge conditions.

Unlike traditional systems SPS does not employ a simplified approach for the determination of surge conditions, instead it uses advanced algorithms for the calculation of the thermodynamic properties of real gases and a model of aeromechanics performances of the compressor.

Through these advanced methods SPS determines the compressor performance under actual operating conditions and identifies also the effective actual surge conditions.

These, as well as other features, allow SPS to exert a complete protection of the compressor even when working in high pressure ranges or with variable input conditions i.e. variable gas composition, or variable inlet temperature and/or pressure.

Differently from other traditional surge protection systems, SPS uses as input the actual gas mix composition. This information can be provided to the system trough an “in line” dedicated instrument (like a gas chromatograph) or as “offline” input trough the operator panel. SPS advanced algorithms allow and extended compressor protection.

Also new diagnostic capabilities, based on the evaluation of compressor actual performances and comparison to the design ones are available.